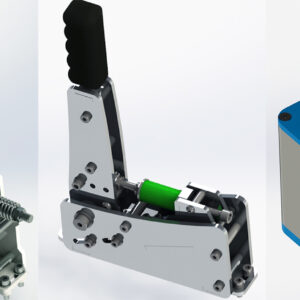

In this tutorial, I will show you how to make an awesome DIY H Shifter for Sim Racing. This 3D Printed H Shifter has a very strong structure, stable and smooth mechanism. I hope you enjoy this tutorial and I wish you good luck.

Here is what I will help you achieve:

The CAD File is here : H Shifter

DIY H SHIFTER REQUIRED PARTS

Find what you need in the DIY Tools section.

Here’s what you’ll need to build the DIY H Shifter.

The Screws

| Diameter x Length – Screws | Quantity |

| M5 x 12 Countersunk | 4 |

| M5 x 12 Socket cap | 4 |

| M6 x 16 Socket cap | 6 |

| M8 x 100 Semi-threated (socket cap smooth) | 1 |

| M8x150 Half Thread Rod | 1 |

| M6 x 10 Socket cap | 2 |

| Diameter – Washers | Quantity |

| M6 | 4 |

M8 Female Rod end [Quantity: 1] [Option: PHS8 Right thread]

3D Printed parts

Springs, Microswitches, Bearings

- Lever spring [Length x Diameter x Wire Diameter: 25 x 18 x 1.8, Quantity: 1]

- Side tension spring 1 [Length x Diameter x Wire Diameter: 40 x 8 x 1, Quantity: 1]

- Side tension spring 2 [Length x Diameter x Wire Diameter: 45 x 8 x 1, Quantity: 1]

- 19x6x6 Bearing [Diameter x Width x Hole: 19x6x6, Quantity: 1]

All required parts

STEP 1: DIY H SHIFTER ASSEMBLY

First step, you need to look at this video (you can skip the arduino part) :

Building Guide

To begin, you need to stick the bearings on the sides of the lever.

Next, you have to insert the screws into the two tension springs, and fix these springs into the holes at the bottom of the case.

Be careful, the two springs have different sizes and must be fixed on the right side.

The springs must be screwed to the mobile part inside.

Now, you need to reverse the arc of the springs by pushing them towards the inside of the case.

Insert the female rodend and the M8x100 screw of the axis. Remember to lubricate this area.

Be careful not to tighten the M8x100 screw too much, otherwise it could distort the case on the other side (where there is the white circle in the second photo). Screw slowly, when the screw head has entered its hole, you will have to stop.

Fix the bottom plate in the right direction to allow the passage of the wires.

Screw the M8x150 bolt on the M8 female rodend. Tighten it well with pliers (this will prevent you from unscrewing it when you go to adjust the gear knob.)

Microswitches mounting

Mount the microswitches, they must be fitted onto the small points provided for this.

If you have difficulty inserting the microswitches, you can extend their holes with a Ø3mm diameter drill bit.

Pass the lever through the M8x150 screw. Don’t forget to grease (preferably with thick grease) the bearings and the M8x150 screw.

Fix the speed plate, the spring (with these two centralizers) and the gear knob. You can adjust the hardness of the lever by tightening/squeezing the spring.

You must check if the lever is at a right angle, and aligned in front of the 3rd gear.

If there is a slight gap, then you will need to adjust the tightness of the bottom screws that fix the tension springs.

You have now completed the assembly of the H Shifter, we will move on to soldering.

STEP 2: DIY H SHIFTER SOLDERING

As for the Sequential Shifter, there are two solutions: Arduino Pro Micro and 0 Delay Usb Arcade Board (the easiest).

For the Arduino solution, here is the soldering diagram:

The Arduino Sketch is provided in the file.

- Arduino Pro Micro Board

- Micro USB Cable

- Arduino software: https://www.arduino.cc/en/software

- Joystick library (mandatory): https://github.com/MHeironimus/Arduin…

Here I will show you the solution with the 0 Delay Usb Arcade Board, which is easier and plug and play.

To begin, you must cut the 2 pin connector. I used this Wire cable stripper.

Pass it from the bottom to the top of the box using the wires passage tunnel provided for this purpose.

Now, you can solder the microswitch.

Just follow the same step for all microswitches.

Clip the microswitches to their respective supports. Remember to place them in the right direction.

Before sticking the microswitches, you must already test them all, to be sure that the lever activates the stop (the click), and if the USB Board and microswitches are recognized in Windows. Check each speed from 1 to R.

If everything is OK, you can now stick the microswitches.

You can finally reassemble the top plate, the spring and the knob, and connect the microswitches to the USB Board at the bottom.

In the bottom plate, there is a space that let you fit the USB Board and the wires. For the 0 Delay Usb Arcade Board, you must print the alternative bottom support named “Extended Bottom Support – Quantity 1.STL” in the Alternative parts folder.

STEP 3: Adjusting your 3D Printed H Shifter

Adjust the hardness of your lever by adjusting the tightness of the knob or by adding the printed washers.

You can mount a real car knob:

- Alternative Knob #1

- Alternative Knob #2

- Alternative Knob #3

- Alternative Knob #4

- Alternative Knob #5

- Alternative Knob #6

- Alternative Knob #7

- Alternative Knob #8

- Alternative Knob #9

Use different Speed plates (5 Speeds, 6 Speeds, 7 Speeds):

You can use two mounting brackets to allow you to mount your shifter wherever you want.

STEP 4: Covering and customization of your DIY H-Shifter

The case has been designed to be covered with the vinyl you like (carbon, etc). All you have to do is cut out a 500mm x 100mm piece and wrap it around the case.

Congratulations ! Your DIY H Shifter is complete, you can now enjoy it in your favorite games.

The CAD files of the 3D Printed H Shifter are available in the shop: H Shifter

If you have any questions or issues while making this DIY H Shifter, you can post in the comment section, I will help you as soon as possible.

-

Product on sale

Pack: Sequential Shifter, H-Shifter and Sim handbrakeOriginal price was: 23.97€.17.99€Current price is: 17.99€.

Pack: Sequential Shifter, H-Shifter and Sim handbrakeOriginal price was: 23.97€.17.99€Current price is: 17.99€. -

DIY Magnetic Paddle Shifters0.00€ (Free)

DIY Magnetic Paddle Shifters0.00€ (Free) -

Product on sale

H ShifterOriginal price was: 7.99€.4.99€Current price is: 4.99€.

H ShifterOriginal price was: 7.99€.4.99€Current price is: 4.99€. -

Product on sale

Sim Racing Sequential ShifterOriginal price was: 7.99€.4.99€Current price is: 4.99€.

Sim Racing Sequential ShifterOriginal price was: 7.99€.4.99€Current price is: 4.99€.