I’m going to list you here good reasons to make your own 3D Printed DIY Sim Racing Pedals. The advantages are the same as for the DIY Sim Racing Pedals.

DIY Sim Racing Pedals: the advantages

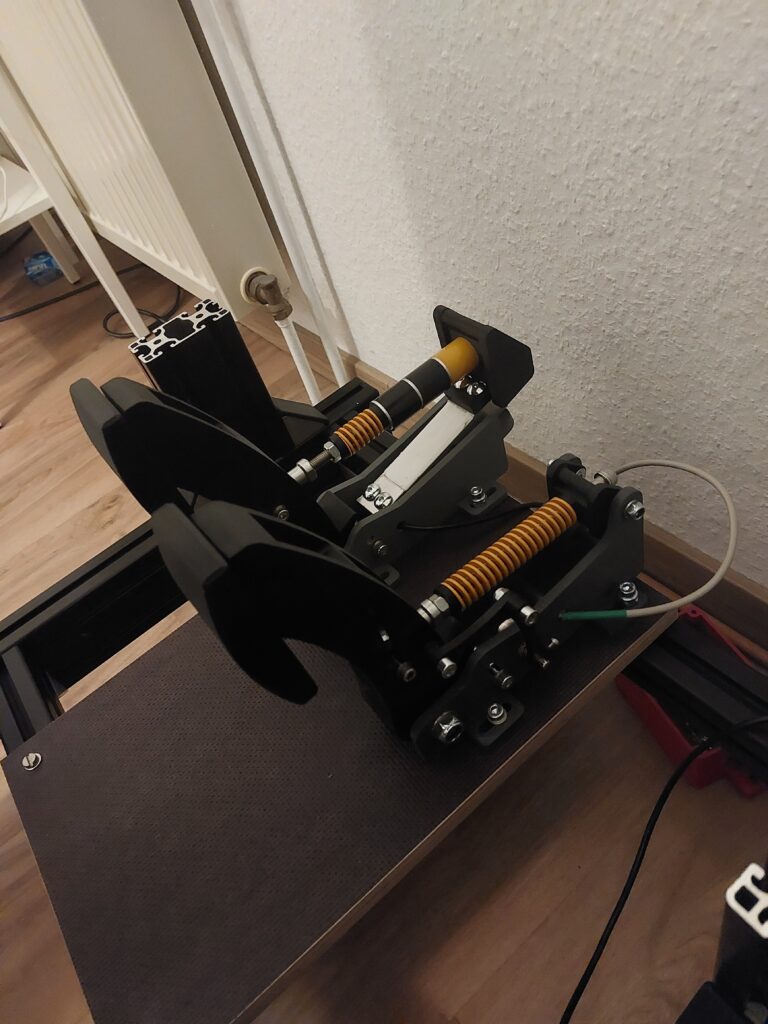

SOLID AS A ROCK

Our DIY Sim Racing Pedals has been designed to support heavy loads (especially for the brake pedal), and in the exceptional case of a broken part, you can always reprint it.

EASY TO MAKE

Assembling this 3D Printed Sim Pedals will be child’s play, you will have no difficulty making it, and to help you, we have written a tutorial with complete and detailed documentation.

FLEXIBILITY

You can configure the pedals according to your driving style by adjusting the hardness of the pedals, the limit stops or the position of the footrests.

PRIDE

You will have the pride of driving with a pedal set made by your hands, and you will also be able to impress your loved ones and family.

SAVE MONEY

Producing pedals via 3D printing can be more affordable than purchasing pre-made ones, especially when considering the customization options.

FREE ASSISTANCE

Need help? We are here to answer all your questions and help you (responses within 48 hours). We make sure all customers finishes their project.

Strength and Durability of your 3D Printed Sim Pedals

MATERIAL SELECTION

The strength and durability of the pedals largely depend on the material used. High-quality filaments such as PLA offer excellent strength and resilience, making the pedals capable of withstanding significant pressure and stress. Here are recommendations for printing 3D solid parts.

DESIGN OPTIMIZATION

3D printing allows for intricate designs with optimized geometry. This means that the 3D printed sim pedals is designed with reinforced structures that provide additional strength without adding excessive weight. The longest part that need to be printed is 220mm.

CUSTOMIZATION AND MAINTENANCE

One advantage of 3D printing is the ease of maintenance and customization. If a part of the pedal wears out or breaks, it can be easily reprinted and replaced. This ensures the overall durability of the pedal system is maintained over time.

SHOPPING LIST FOR YOUR DIY SIM RACING PEDALS

SPRINGS AND ELASTOMERS

- Throttle Spring [Quantity 1] [Option: Length: 90mm, Diameter: 20mm]

- Throttle Spring alternative 1 [Quantity 1] [Option: length 90mm, Diameter 20mm]

- Throttle Spring alternative 2 [Quantity 1] [Option: Color: yellow, Specification: 18x9x100]

- Brake Spring [Quantity 1] [Option: Length 30mm, Diameter 20mm]

- Brake Spring alternative 1 [Quantity 1] [Option: Length 30mm, Diameter 20mm]

- Brake Spring alternative 2 [Quantity: 1] [Option: Color: yellow, Specification: 18x9x40]

- Clutch Spring [Quantity 1] [Option: Length: 90mm, Diameter: 20mm]

- Bushing/Elastomers [Quantity: 2 minimum] [Option: 85A or/and 90A]

- Alternative link for Elastomers #1

- Alternative link for Elastomers #2 [Quantity: 3 minimum] [Option: D25/8,5x25mm]

- Alternative link for Elastomers #3

- Alternative link for Elastomers #4

- Alternative link for Elastomers #5

- Solution-elastomeres [Options: Length 250mm, External diameter Ø32mm, Internal diameter Ø8,5mm, Shore/Hardness 80-90-99]

POTENTIOMETERS AND LOADCELL

- P260 potentiometer [Quantity: 2]

- Potentiometers alternative [Quantity: 2] [Option: 10k Ohm]

- Brake Loadcell [Quantity: 1] [Option: 120kg]

USB BOARDS (only one of them is mandatory)

- Leobodnar BU0836-LC 12-bit [Quantity: 1]

- Leobodnar LC-USB 16-bit [Quantity: 1]

- USB Type A to B for Leobodnar and DSD boards [Quantity: 1]

- DSD 12 Bit Controller [Quantity: 1] [Option: 12 Bit Controller with AMP]

- DiyMore Arduino Leonardo board [Quantity: 1] Note: only with HX711 Loadcell Amplifier

- Micro USB cable for DiyMore Arduino Leonardo board [Quantity: 1] [Option: 3m]

- Arduino Pro Micro [Quantity: 1] [Option: Mini USB 3-6V] Note: only with HX711 Loadcell Amplifier

- Mini USB cable for Arduino Pro Micro board

- HX711 Amplifier (Option: Standard Board)

- Alternative Sparkfun HX711 Loadcell Amplifier [Quantity: 1]

3D PRINTER

- CREALITY 3D Printer Ender-3

- AnyCubic Photon Mono X

- AnyCubic Kobra 2 Neo

- PLA Filament 1.75mm

- PLA Filament 1.75mm alternative

REVIEWS OF THE DIY SIM PEDALS

“In regards to the 3D printed version I will say I try to beat these up so hard, I smashed on them, I really figured they would break they just didn’t in my testing.” – Shaun Cole (The SimPit)

BUILDING OF THE DIY SIM RACING PEDALS

How to make a DIY Load Cell Pedals

Would you like to make your own DIY Sim Racing Pedals for your Sim Racing Setup ? You are in the right place.This tutorial provides step-by-step instructions to help you build high-quality and customizable 3D Printed Sim Racing Pedals.

The building of this pedal is quite easy. If you love crafts and DIY, you will have a great time making it.

Very good and budget friendly project. Any question was quickly answered by author. I can recommend it to everyone

Great work 🙂 the 3d printed pedals are a solid choice! The build is a two pedal version, without a clutch. My T3pa pedals are like a toy in comparision. The whole project was a great experience and the support from Diysimstudios was more than awesome :)) any question was answered very quickly via Email. Highly recommend to do that diy project. Best regards and have fun 😉 Jonas